In industrial control and power systems, there is a crucial but often misunderstood component – AC contactor. You may have encountered it when dealing with large motors, HVAC equipment or high-power lighting systems.

This AC contactor guide will help you quickly master the basic knowledge of this important electrical component, AC contactor fault symptoms and practical replacement skills, so that you can confidently deal with power control problems.

What is an AC Contactor ?

AC contactor is an electronic control switch for remote control circuits, especially suitable for frequent switching on and off large current circuits. It is mainly used for starting, stopping, accelerating, braking and reversing AC motors and other power equipment.

The contactor is essentially an electromagnetic switch. Its main task is to quickly and reliably connect ( close ) or disconnect ( open ) the power supply of the main circuit when the control signal is received. Its function is similar to the relay, but it is usually used to deal with larger current and voltage than the relay.

In addition to the AC contactor, there is also a DC contactor. DC contactors use DC power to drive coils and are commonly used to control DC loads such as electric vehicles, forklifts and DC power systems.

What is the difference between AC contactor and DC contactor ? The main differences are the working power supply of their coils, the design of the arc extinguishing system ( AC has a natural zero-crossing point, while DC does not, so DC contactor arc extinguishing requirements are higher ) and the type of load they are usually used to control.

What is the Working Principle of AC Contactor ?

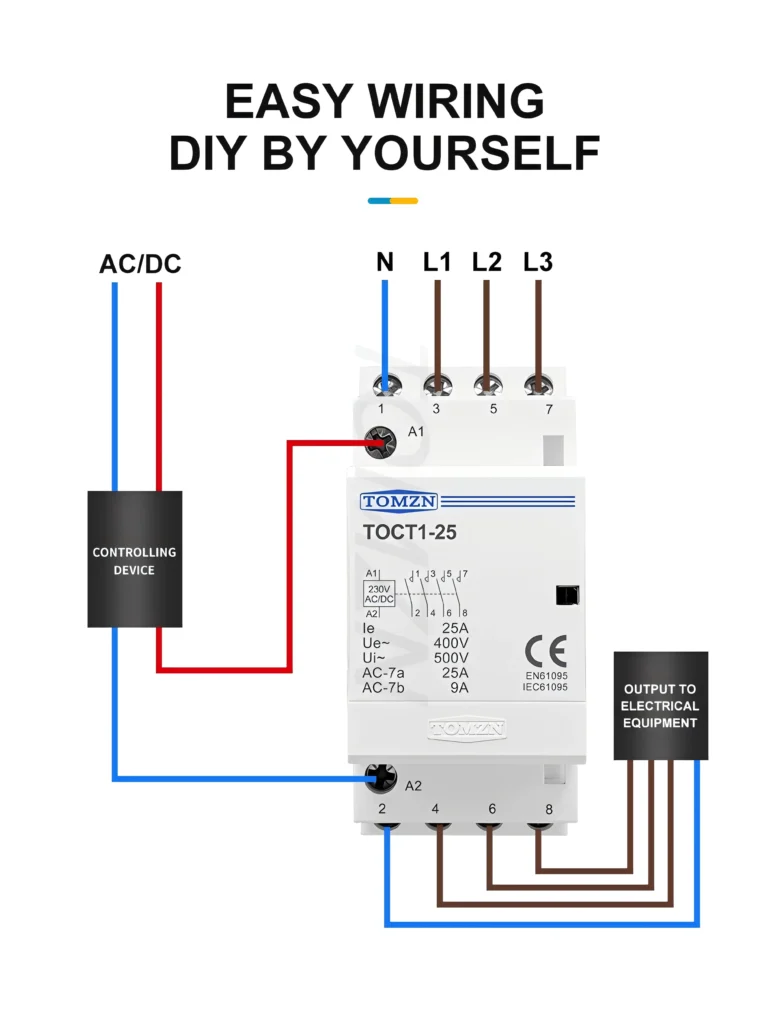

( Wiring Diagram of A Contactor )

The working principle of AC contactor is based on electromagnetic attraction.

Coil energization ( control voltage ) : When the control power supply ( usually the control voltage of the AC contactor is much lower than the main circuit voltage, such as 24V, 110V, 220V, etc. ) is applied to the electromagnetic coil of the contactor, the current is generated in the coil.

Generate magnetic field : Current flowing through the coil will produce a strong electromagnetic field.

Pull-in : This electromagnetic field will attract the armature ( movable core ) inside the contactor.

Contact closure : The movement of the armature drives the main contact to close. The main contacts are connected to the main circuit. After they are closed, the current of the main circuit is allowed to flow through, thereby supplying power to the load ( such as the motor ).

Coil power off : When the control power is removed, the electromagnetic field disappears.

Release : Under the action of the spring force, the armature returns to the initial position and the main contact is disconnected, thereby cutting off the current of the main circuit and the load stops working.

How to operate the AC contactor ? By simply controlling the power on and off of the coil to operate the contactor, the start and stop of the equipment connected to the main circuit ( such as the motor ) can be controlled.

Signs of AC Contactor Failure

Understanding the fault symptoms of AC contactors is helpful to find and solve problems in time and avoid greater damage to the equipment.

Unable to pull or release : After the contactor coil is energized, the main contact is not closed ( unable to start the load ) or after the coil is powered off, the main contact remains closed ( the load cannot stop ).

Abnormal noise : The humming or abnormal noise of the contactor during operation may be caused by loose iron core, damage of short-circuit ring, poor contact or improper voltage. Abnormal noise and heating are often associated, and abnormal heating of contactors can also affect their life.

Contact welding or burn : Contacts are severely heated, have a burnt smell or visible burn marks. This is usually caused by excessive load, frequent operation or insufficient contact spring pressure.

Control loop problem : The control signal has been sent, but the contactor has no response.

How to judge whether the AC contactor is damaged ? By examining the above symptoms, combined with the following test steps to confirm.

How to Test AC Contactor ?

Before any test or AC contactor maintenance, be sure to cut off all power to ensure safety.

1. Check the coil

Objective : To check the electromagnetic coil is intact.

Methods : Use the resistance of the multimeter to measure the resistance at both ends of the coil.

Judgement : The measured resistance should be close to the coil resistance value marked on the product nameplate. If the resistance value is shown to be open ( infinity ), the coil is damaged.

2. Check the main contact

Objective : To check the conductivity of contacts in different states.

Methods :

- Release state ( coil is not energized ) : measure the resistance at both ends of the main contact ( usually the normally open contact, NO ). They should be in a disconnected state ( resistance infinity ).

- Pull-in state ( coil energized or manual pressing ) : How to check the conductivity of the AC contactor in the pull-in state ? Manually press the armature to pull it in, and measure the resistance at both ends of the main contact again. They should be on ( resistance close to 0 ohms ).

3. Check the auxiliary contact

Objective : To check the switching function of auxiliary contacts ( such as normally closed NC and normally open NO ).

Methods : In the release and pull-in states, the resistances of the auxiliary contacts were measured respectively to ensure that they can reliably switch states.

Note : The safest way to test the AC contactor is the power-off test. If you need to test the coil voltage, please be operated by a professional.

How to Replace the AC Contactor?

If it is determined that the contactor is damaged, an AC contactor replacement is required.

1. Preparation work

- Power off : Before starting to work, the power supply of the main circuit and control circuit must be completely cut off and the power test must be carried out to ensure safety.

- Record wiring : Take a clear picture of the old contactor, or draw a detailed AC contactor wiring diagram, record the position and color of all the connecting lines including the main line and the control line.

- Purchasing new contactors : Ensure that new contactors fully match old contactors in terms of rated current, rated voltage, coil voltage and contact type ( e.g. unipolar AC contactors or other poles ).

2. Remove the old contactor

After marking all wires, carefully remove the wires connected to the main contacts and coil terminals.

Loosen the fixing screw or remove the old contactor from the DIN rail.

3. Install a new contactor

Install the new contactor to the appropriate location.

Reconnect all wires according to your recorded AC contactor wiring diagram. Ensure that all wiring is firm and reliable, especially the wiring of the main circuit, must be tightened to avoid heating caused by poor contact.

4. Test

Firstly, it is sent to the control power supply for no-load test ( without connecting the main circuit load ) to confirm that the pull-in and release functions are normal.

After confirming the correctness, it is sent to the main circuit power supply for on-load test.

Cost reference : The replacement price of AC contactor varies with the model, rated current, brand and labor cost of the contactor. It is recommended to consult the local professional electrician quotation.

How to Select the Right AC Contactor ?

| Consideration Factors | Explanation |

| Rated operating voltage ( Ue ) | The maximum voltage that the main contact of the contactor can withstand must be greater than or equal to the load voltage. |

| Rated operating current ( Ie ) | The current of the main contact of the contactor that can work for a long time under the specified conditions must be greater than the actual working current of the load and leave a margin. |

| Coil voltage | This is the control voltage of this AC contactor. Must be consistent with the supply voltage of your control loop ( e.g.24VDC, 220VAC ). |

| Load type and usage category | The appropriate contactor is selected according to the load type ( such as AC-1 for non-inductive or micro-inductive load, AC-3 for squirrel-cage motor start-up and power off during operation ). |

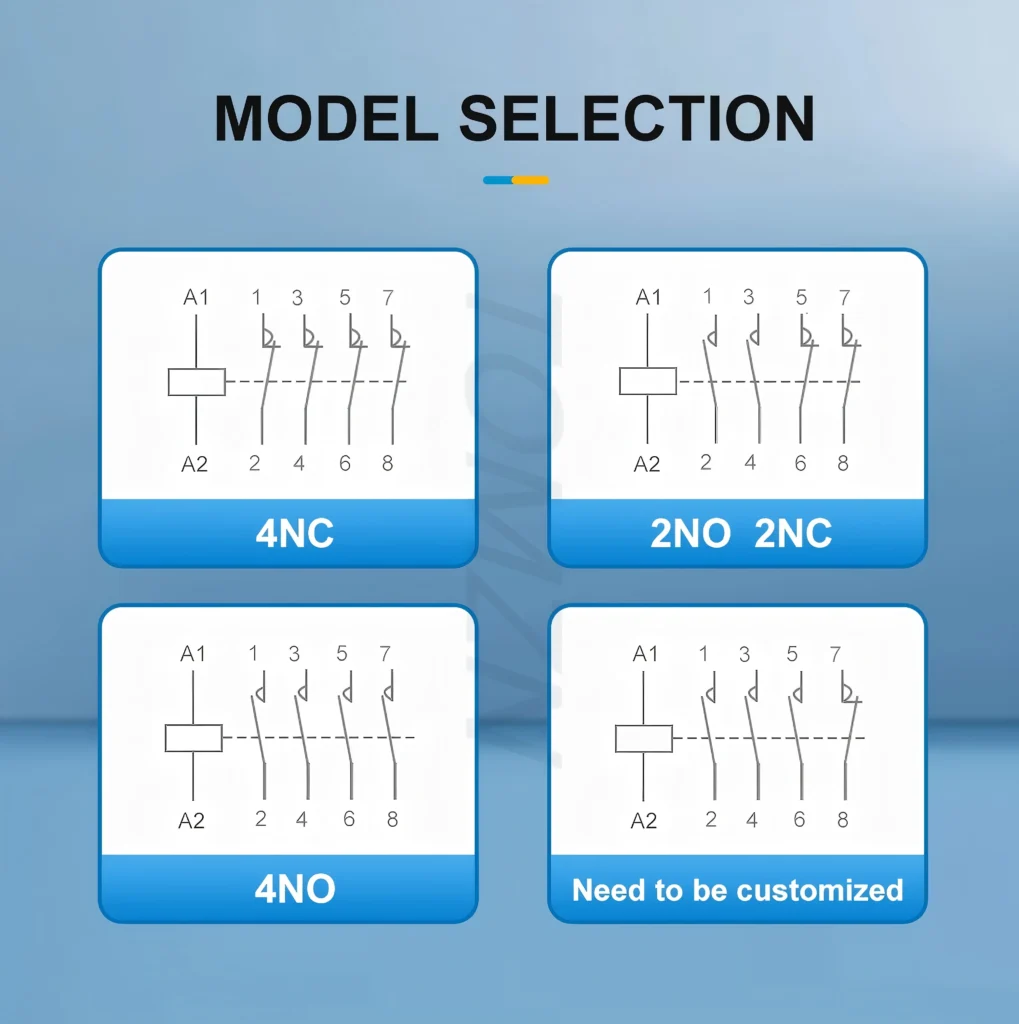

| Number and type of contacts | Ensure that the number of main contact poles ( such as unipolar AC contactors, triodes ) and the required auxiliary contacts ( normally open / normally closed ) meet the control requirements. |

| Operating frequency | Frequent operation will affect the service life of the AC contactor. If the operation is very frequent, wear-resistant and high-life contactors should be selected. |

Conclusion

With 20 + years of expertise,TONZM supports global agents through a collaborative ecosystem supported by ISO9001, CCC and CE certifications. Our global network spans 30 + countries / regions, providing end-to-end support for competitive growth.

In terms of high-quality electrical products, TONZM company specializes in the production of MCB, MCCB, RCCB, RCBO, SPD, ATS, MTS, overvoltage and undervoltage protectors, disconnectors, Wi-Fi intelligent products, photovoltaic DC products, digital display instruments, switching power supplies and other products. Provide rich memory to meet the needs of a variety of different electrical systems.

How Long is the Service Life of An AC Contactor ?

The life of the contactor is divided into mechanical life and electrical life. Mechanical life ( non-electric operation ) can usually reach millions of times ; electrical life ( charged operation ) depends on the type of load and operating frequency, generally between tens of thousands to hundreds of thousands of times. Frequent high current operation will significantly shorten the electrical life.

How to Judge Whether the AC Contactor is Damaged ?

By observing whether there is abnormal noise, burning smell, the main circuit can not be connected or disconnected. The most reliable method is to use a multimeter to check the coil resistance and the conductivity of the contacts in the pull-in / release state.

Can A DC Contactor Be Used for Alternating Current ?

Usually not recommended. Although some DC contactors may work reluctantly under low current AC load, their arc extinguishing system, coil design and core structure are designed for DC characteristics. When used for AC power, they may cause serious coil heating, unreliable closing, loud noise, and rapid damage.

Does the AC Contactor Affect Heating ?

Yes. During normal operation, the main contact and coil will generate heat due to the passage of current, but it should be within the rated temperature range. If the AC contactor will affect the heating ? The answer is yes, and abnormal heating is usually a sign of failure, such as poor contact or coil voltage mismatch.