PV Combiner Box is an essential component in photovoltaic (PV) power generation systems that plays an important role in connection and protection during solar power generation.

With the development of the PV industry, the application of combiner boxes is becoming increasingly widespread. It’s necessary to understand the functions and application. This article will provide a detailed introduction to the basic concepts, main functions and selection of solar PV combiner boxes.

What is a PV Combiner Box ?

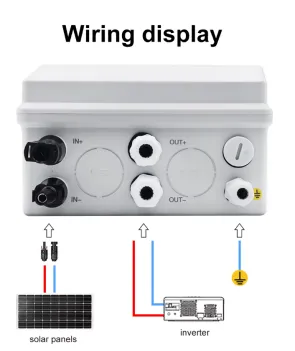

PV Combiner Box , also known as solar combiner box, is a device that collects the DC current from multiple photovoltaic modules. It is typically located in the middle of the PV power generation system that is responsible for collecting the current generated by the photovoltaic modules to the inverter or other electrical equipment. A solar combiner box can integrate necessary protective devices such as fuses, switches and surge arresters according to actual needs that ensures the safe and stable operation of the system.

Why are PV Combiner Box Needed?

PV Combiner Box not only has the most basic current collection function, but also:

Overcurrent protection

Each input is equipped with a DC fuse or DC circuit breaker.

When a short circuit occurs in a solar panel string, the fuse for that string will quickly blow, isolating the fault and preventing it from escalating and affecting other normally functioning strings or even damaging the expensive inverter.

Lightning and Overvoltage Protection

A PV combiner box is equipped with a surge protector that protects the system from instantaneous high voltage (surge) impacts caused by lightning strikes or grid operations.It prevents equipment damage from high voltage.

Disconnect Switch

A PV combiner box is equipped with a main DC disconnect switch.

When system maintenance or repair is required, the main output of the combiner box can be manually disconnected to ensure that the downstream circuits are de-energized. It guarantees personnel safety.

Monitoring and Intelligent Management

Because the photovoltaic industry has become more popular, intelligent PV combiner boxes have also acquired more advanced functions. They are equipped with current and voltage sensors and communication modules.

This allows for real-time monitoring of the current, voltage and power of each string. Maintenance personnel can remotely view the data on a computer or mobile phone. If an abnormal current is detected in a particular string (e.g., zero current), the problematic string can be quickly located, greatly improving maintenance efficiency.

How does a PV Combiner Box work?

1. Collection: Each solar panel generates DC power, which is input to the combiner box through its respective input port.

2. Combining: Inside the combiner box, the outputs from each panel are combined into a single DC output.

3. Protection: The combiner box is equipped with protective devices such as fuses or circuit breakers to prevent overcurrent.

4. Monitoring: Advanced combiner boxes also include monitoring functions for tracking performance and diagnosing problems.

What Components are a Photovoltaic Combiner Box Inside?

DC Molded Case Circuit Breaker

DC MCCBs are used to protect circuits in solar power systems. When a short circuit occurs in a solar string, a large fault current is generated. The corresponding fuse will quickly blow (or the circuit breaker will trip) that isolates the faulty string and prevents it from affecting other normal strings and damaging downstream inverters. The rated current of the DC molded case circuit breaker is 63A to 630A that is suitable for high-power photovoltaic systems.

PV fuses melt in case of an accident that prevent reverse current from continuing to flow and protect cables and other equipment from further damage.

DC surge protection devices protect against instantaneous high voltage (surges) caused by lightning strikes or grid fluctuations. They instantly divert surge current to the ground that limits the voltage to a safe range and protects all equipment inside the box from high-voltage damage.

PV Combiner Box Installation and Maintenance Precautions

When installing a solar combiner box, choose an easily accessible location for maintenance. This facilitates routine upkeep.

The TOMZN team recommends that the PV combiner box should be installed in a north-facing location to receive more shade. Placing the PV combiner box in direct sunlight can cause the internal wiring to overheat.

Additionally you should install the combiner box in a location that effectively protects it from the effects of natural elements.It can be used for a long time.While they are typically waterproof, additional protection is still essential. Finally it’s best to choose a location close to existing solar panels. This minimizes wiring and significantly reduces the risk of electrical faults between solar panels and the combiner box.

What Should You Pay Attention to When Buying?

When selecting a photovoltaic (PV) module, you need to comprehensively consider factors such as the scale of the PV power plant, the installation environment and the operation and maintenance methods.

Choose an appropriate number of input circuits

Select the appropriate number of input circuits based on the number of photovoltaic arrays. Photovoltaic combiner boxes typically have multiple input channels such as 4, 6, 8, or 12. The number of input circuits should match the number of photovoltaic module strings to avoid insufficient circuits leading to difficulties in future expansion and to avoid excessive circuits causing resource waste.

Simple principle: Number of module strings ≈ Number of combiner box circuits.

Confirm that rated voltage& rated current.

Before purchasing, you need to determine the maximum system voltage of the photovoltaic modules (e.g., 1000V or 1500V) and the current per string and ensure they match the rated specifications of the combiner box.

- Low rated voltage will cause equipment to malfunction.

- Insufficient rated current may pose a risk of overheating or damage.

Select the protection level according to the operating environment

Outdoor photovoltaic power stations typically require combiner boxes with an IP65 or higher protection rating to prevent dust, rain and moisture ingress.

For harsh environments such as high temperatures, coastal areas, sandstorms or high altitudes, consider:

- Corrosion-resistant metal or non-metal enclosures

- Enhanced sealing design

- Intelligent models with temperature and humidity warning functions.

Prioritize intelligent combiner boxes with monitoring capabilities

Intelligent combiner boxes can monitor parameters such as current, voltage, temperature and lightning protection status of each circuit in real time and upload this data to the operation monitoring platform via a communication interface. They are particularly suitable for distributed power stations and large ground-mounted power stations.

- Quickly locate faulty strings

- Improve operation and maintenance efficiency

- Reduce manual inspection costs

Choose stable and reliable products

Compliant products typically pass the following certifications or tests:

- Safety certifications such as CE, TUV, CCC, CQC, etc.

- Lightning protection devices comply with national or IEC standards (such as GB/T18802)

Q: How many combiner boxes are needed for a solar system?

A: There is no fixed answer to how many combiner boxes are needed for a solar system; it depends entirely on the system design and scale.

The calculation formula is: Number of combiner boxes = Total number of strings ÷ Number of input channels per combiner box

Q: Does a solar combiner box increase the voltage?

A solar combiner box itself does not increase the voltage, but its total output voltage after combining the current will be equal to the voltage of each string input to it.

Q: What is the difference between a combiner box and a distribution box?

A combiner box and a distribution box are two completely different electrical devices in a photovoltaic system. The combiner box is responsible for “collecting” current, while the distribution box is responsible for “distributing” power.